4 Advantages of 3D Laser Scanning When Designing a Product

The invention of the 3D technologies has paved a way for many possibilities for designing a product. 3D laser scanning is one such technology that helps manufacturers or designers in creating 3D models with the help of simple mathematics and laser light. There are various advantages of using 3D laser scanning while designing different models. Let us have a look at these benefits one by one:

1. Offers more speed

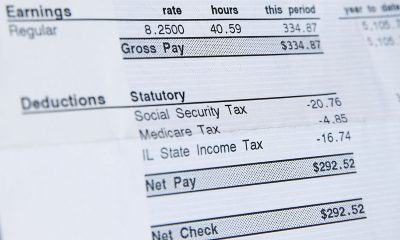

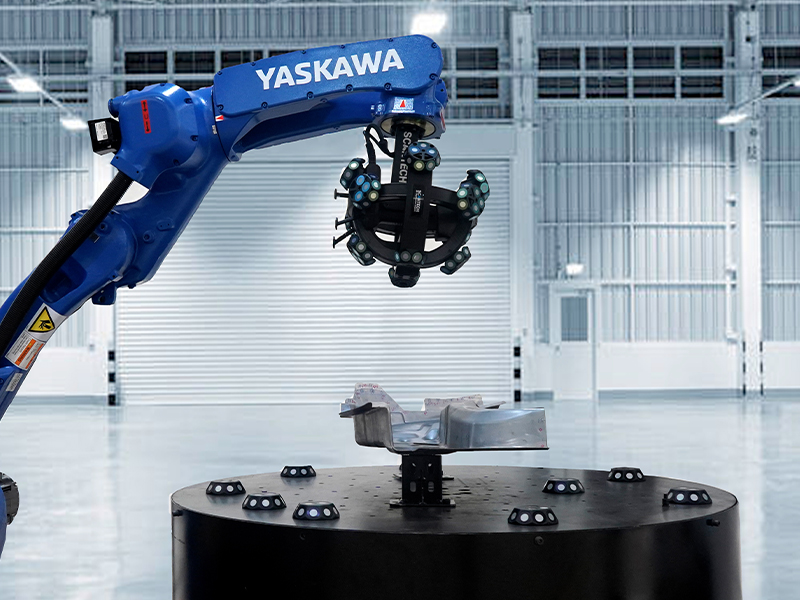

Source: 3d-scantech.com

Traditional devices such as hand tools and CMM can only measure one data point at a given time. This makes the whole process very time-consuming. But this does not happen with the 3D laser scanning. When the laser moves on the surface of any object, it can record thousands of data points within a second, which means it provides more speed than the conventional tools. The entire scanning can get completed within hours depending upon the size of the object.

2. More accuracy and efficiency

Source: 3d-scantech.com

A 3D laser scanner provides more accuracy and efficiency than other methods. The number of errors produced by using this technology while designing a product is very less as compared to traditional tools.

An accuracy of 0.0002 to 0.197 can be achieved with the help of the 3D scanner, depending upon its specification and the climatic conditions in which you are scanning the product. When you get accurate results in the first place only using professional 3D scanners, your work gets reduced automatically for the next stages in the designing process.

3. Cost-effective

As mentioned earlier 3D laser scanning saves your time because of its speed, so the labor required is also less. This implies that the entire designing process becomes cost-effective. You can easily outsource the 3D laser scanning device from another company at an affordable price. It means that it not only helps in saving your time but also your money. So, if you have a restricted financial plan, then using 3D laser scanners would be helpful than other traditional technologies.

4. Safe to use

Safety of the workers is the main concern at any construction site. 3D laser scanning is the best tool that ensures safety of the designers working with it. Such devices are capable of measuring the data points even from a great distance from the object. This helps in keeping the operator safe from any toxic condition and dangerous topography. They do not have to go close to any chemical or nuclear facility that can be harmful for their health. Also, the time consumed by this device is less, which means less exposure to dangerous conditions.

To Sum Up

3D laser scanning has become a popular device for designing different products by using laser light and simple calculations. It offers many advantages over the other conventional technologies. It is more accurate and efficient than other tools like CMM. The biggest benefit of using 3D laser scanners is that it provides safety to the workers on the construction site. The workers do not have to go near the harmful chemicals as this technology offers non-contact scanning.