4 Ways Digitalization Can Improve the Overall Performance Within Your Factory

Digitalization of the business in the factory can bring so many different benefits, and best of all is they can be applied to factories of all sizes and fields. Companies have the opportunity to improve their competitiveness, to stand out, and to become more efficient and profitable in terms of business by embracing digitalization. However, factories need to have a clearly defined strategy in order to ensure that all workers are familiar with the changes.

In general, a factory’s overall income, as well as the profit, will depend on how it operates. This is exactly what digitalization comes in hand with since it can enhance how the factory works, reduce costs, and highlight new products on the market easily.

As you probably know, all users are now searching online before they buy any product. Therefore, all factories and companies need to accept the digital world, because other competitors will.

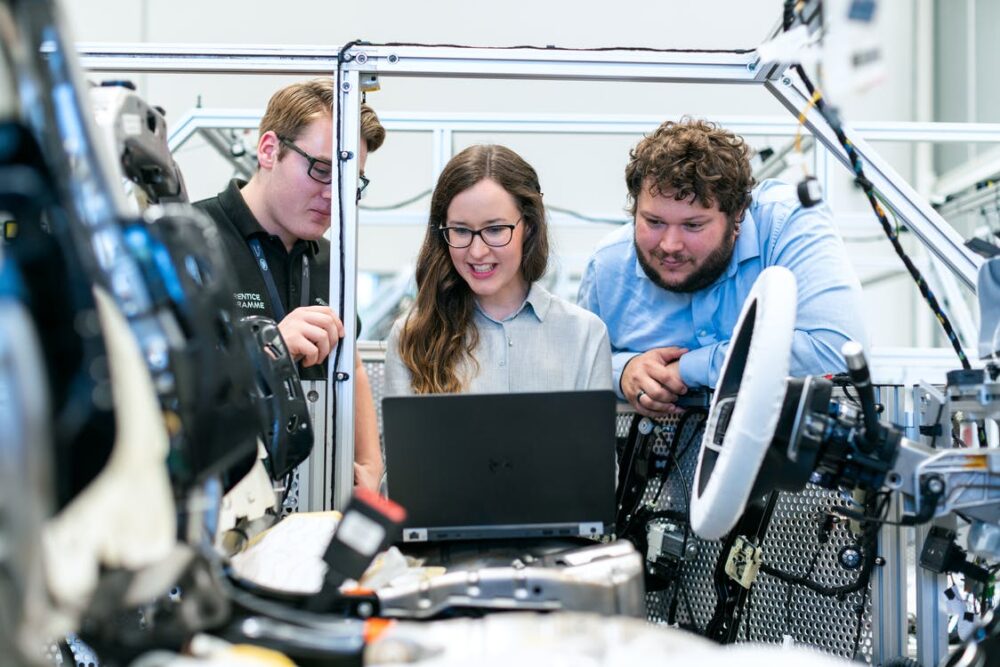

1. Digitalization provides increased Efficiency and Productivity

Source: forbes.com

Digitalization can improve the overall performance within your factory by increasing the efficiency as well as the productivity of your business. Technology has always been a synonym for efficiency. Therefore, factories need to ensure that their systems, processes, and overall performance are created in a way to allows workers to operate smarter and easier in the factory.

In other words, factories need to take advantage of the easier operation options, instead of currently harder ones to improve their profit and productivity. When a factory adapts the latest technology features, a business can achieve higher processing levels. Additionally, with Artificial Intelligence and learning machines, the overall performance will be automated and tasks are going to be completed incredibly faster.

2. Digitalization provides Better Resource Management

Source: pinterest.com

In general, it is incredibly significant for one factory to have the right resources in place since the market is highly competitive. Just because of that, one of the primary goals of one factory needs to be the maximization of the resources on its own for the purpose of optional growth. This counts for capital, labor, and for suppliers, and inventory. One of the things that are adopted widely in different factory businesses is cloud computing because it supports resource sharing across many different departments included in one company.

This feature refers to one of the IT highlights. Best of all is that this cloud can even allow businesses to pay for only the resource they actually need which means that this is a very budget-friendly option.

Additionally. IoT – the internet of things is also helping factories in their business in the aspect of tracking the resources in real-time. This provides high visibility into how resources are being used and according to that data, the particular factory can implement some improvements that are required for effectiveness. All of the mentioned things are referring to very good operations with resource management.

3. Digitalization provides improved Customer Engagements

Source: pinterest.com

As we mentioned, we are truly living in a highly competitive business environment. Since there are so many different factories that want to highlight their business field and their products, they are looking to find a way to stand out somehow. In general, one of the task that business needs to achieve is to engage with their customer in a meaningful manner. This is exactly where technology comes in help.

More precisely, digitalization can provide factories tools that will help them to understand the customer needs and how to make them satisfied. For instance, data analytics, as well as Artificial Intelligence, are used to develop special customer profiles. These details can actually target a specific group of clients and be used to provide personalized customer experiences.

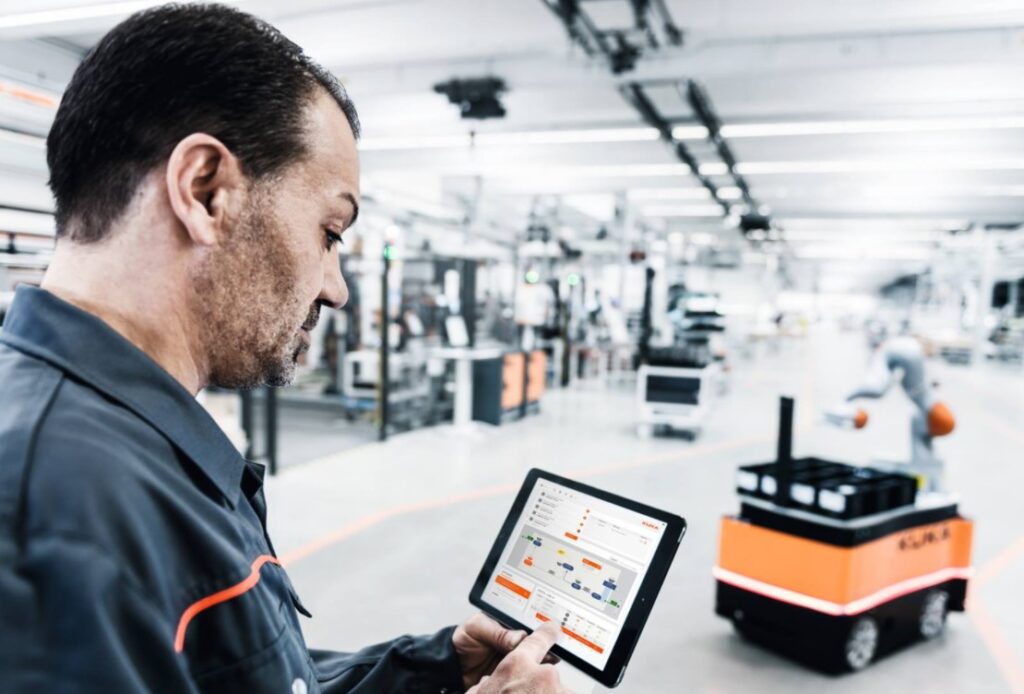

4. Digitalization provides Increased Responsiveness To Business Needs

Source: pinterest.com

Digitalization can improve the overall performance within your factory by increasing responsiveness which is now a very important factor for every business field. As you are noticing, the market is constantly growing and evolving, which means that all businesses and factories need to make sure that they can keep up with the market standards. In other words, it would be best for their success to offer something innovative. Top factories are not implementing IT systems that offer them flexibility and scalability. These things are allowing the particular factory to stay agile and respond very fast when it comes to the occurrence of different business needs.

Factories need to invest in the digitalization roadmap if they want to determine their ability and performance and to remain competitive in the future as well. Additionally, factories and companies that are adopting AI-based technology systems that are performing repeatable tasks are actually helping their workers to focus on more valuable work that requires human operation and intelligence. Robotic and automatic performance can assist human workers and as the result, high-quality customer service will be provided.

Are you ready to bring your factory to the next level and actually stand out from the competition?

Source: pinterest.com

Every factory in the world needs to meet industry standards. However, it is completely normal that they are facing different problems, challenges, and obstacles that they need to overcome. For instance, some of the most common problems are referring to low safety awareness of the employees, lots of resource wasting, outdated operations, and instructions that workers need to follow on paper. Additionally, many of them are operating inefficiently and they are not focusing on improving that operation.

Despite that, since they are not focusing on improving and developing options from which they can benefit, their operations are very time-consuming. We have good news for you since you can easily meet industry standards and improve overall factory performance in an easier and more effective way by using platforms made for those purposes.

Not only that overall results will be highly successful with this platform, but the safety and quality of the operation will be significantly improved. If you are interested to find out more details about this visit this website. You are going to find solutions for many different problems that one factory can faced with. As a benefits of the digital platform of this kind you can also prevent risk of unsafely incidents, despite improving the product quality, operation work, and increasing profit.